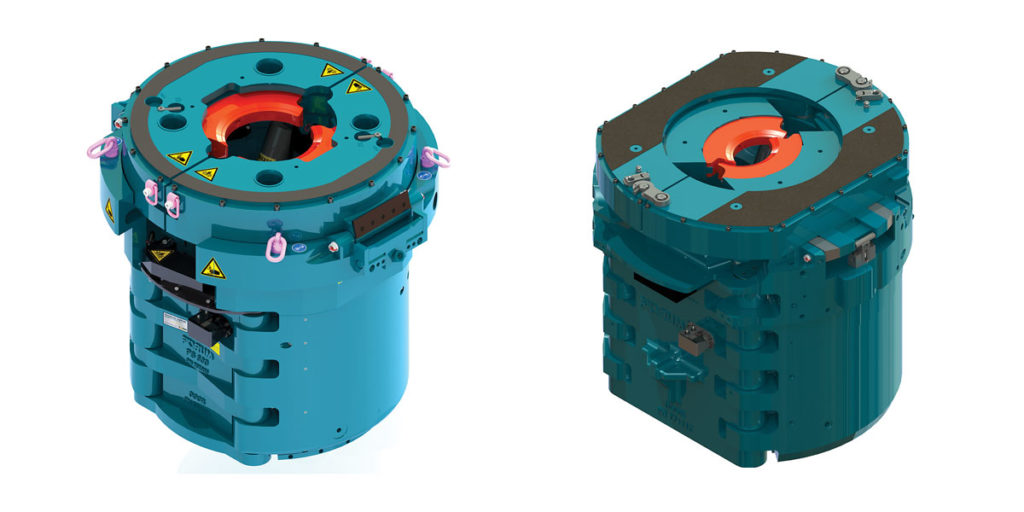

Power (or automatic) drill pipe slips are used to securely suspend tubulars while permitting crews to perform a full range of downhole tasks. By offering a powerful grip while transferring the loads from elevators, power slips keep crews safer while preventing pipe and slip damage caused by sudden movements or overloading.Forum power slips are designed to maximize both safety and efficiency. Installed nearly flush in the rotary table, they de-clutter drill floor space and prevent slip-related injuries from tripping, pinching and lifting. Remote operation from driller cabins keeps personnel out of harm’s way, and integrated top guide systems ensure safe, firm and error-free gripping. Forum Power Slips allow quick installation and carrier assembly changes, maximizing uptime.Multiple hydraulic power slip/elevator designs are available to handle long, heavy tubulars up to 22 inches with load weights up to 1,500 tons when installed in rotary tables. Offering flexible interchangeability among assemblies and insert carriers, a single frame supports all unit sizes. All Forum power slips are manufactured to the highest industry standards including the American Petroleum Industry (API).

FEATURES (ACROSS ALL MODELS)

- Pipe sizes up to 22 inches

- Load weight capacities up to 1,500 tons

- Compatible with API rotary tables

- Back-up torque up to 120,000 foot/pounds

- Patented clamping systems

- Hydraulic feedback for slip-ups and slip-downs

- Central greasing systems

- Top guide systems

- Off-the-shelf inserts

- Multiple adapters for rotary tables/original equipment manufacturers

- Remote or standalone operation

- Compliant with API 7K standards

- Options: hand slip insert bowls, reduced bushings, wear guides, multi-coupling kits, pipe wiper systems, bit breaker adapter plates, etc.

Comments

0 comments

Please sign in to leave a comment.